•ISUZU 700P Truck Chassis

•4HK 190HP Diesel Engine

•CB10/30 Fire Pump

•PL24 Fire Monitor

•Water Tank 5000Liters

1. Features

² CHASSIS: CSC5100GXF30 Water Tank Fire Truck mounted base on the ISUZU fire vehicle chassis, 6 nos. (include driver) of crew cab. The fire truck featured with its comfortable and reliable to drive. The 4× 2 driving mode with a maximum driving speed 105km/h. ISUZU make vehicle engine model 4HK1-TCG, output power 139kW.

² TANKER: Built-in water tank and foam tank, Water Tank Volume 5000kg, Tank Body is made of stainless steel material.

² FIRE PUMP: The fire truck takes power from the chassis transmission and drives the CB10/30 fire pump (Shanghai Rongshen Brand)installed in the rear pump room of the fire truck through a universal coupling drive shaft. The fire pump has a rated outlet capacity of 1800LPM at pressure of 1.0MPa.

² FIRE MONITOR: The fire truck roof is installed with WST (brand) PL24 (model) Water, Foam double-purpose manual-control fire monitor, rated flow capacity 1440LPM at maximum pressure 1.0MPa, with a performance of water shooting range ≥55m, 360° rotation.

² CONCLUSION: The truck is designed to be able to carrying equipment and firefighters and the tank providing water and foam which go through a mixture pump rear or front mounted, use a monitor mounted on top of the truck to fight a fire occurs in places such as oil plants and chemical factories to cool the fire and to coat the fuel, preventing its contact with oxygen for fire suppression and finally extinguish the fire completely.

2. General Specifications

Item | Specification |

Dimension (min) | 8445×2308×3250mm |

Wheelbase | 5200mm |

Maximum weight | 8200kg |

Water Tank Capacity | 5000liters |

Tire size/no. | 8.25-16 /6+1 no. |

Engine power | 141kW(2600r/min) |

Transmission | MLD 5 speed forward |

Suspension | Front leaf spring 8 nos Rear leaf spring 10+6 nos |

Max. driving speed | 105km/h |

Approach/ Departure angle | ≥12°/≥17° |

Min turning radius | 12m |

Fire pump capacity | |

Fire monitor capacity | |

Fire monitor reach | Water ≥55m |

Crew numbers | 3+3 |

Unit rating | 221/16≥13.81 |

3. Engine Specifications

Model number | 4HK1-TCG |

Make | ISUZU |

Cylinders | 4 cylinders inline |

Air inlet | Turbocharged intercooling |

Type | Electric 1800bar common rail, DOC |

Engine power | 141kW |

Displacement | 5193ml |

Emission glass level | Euro 4/5 |

Torque (speed) | 510N·m(1600r/min) |

Fuel Consumption | ≤210g/kW.h |

Bore x stroke | φ115×125mm |

4. Crew Cab Specifications

Structure | Flat head, four doors, double row seat, hydraulic tiltable structure | |

Crew numbers | 3+3 | |

Self-container breathing apparatus | 3 nos | |

Driver side | Left hand drive | |

| The original truck chassis is equipped with: high comfort adjustable driver's seat, single adjustable front passenger seat, standard heating and cooling air-conditioning system (R134A refrigerant, no Freon), radio + USB, power windows on both sides of the front row, both sides Rear view mirror, right side lower mirror, right front side lower mirror. Fire truck manufacturer installed: Self-container breathing apparatus in rear sets; front power supply and warning light alarm, water pump power take-off switch, etc. | |

Instrument | 1. Vehicle speedometer. 2. Fuel gauge, tachometer, reverse gear horn, etc. | |

5. Fire Package Specifications

² STRUCTURE

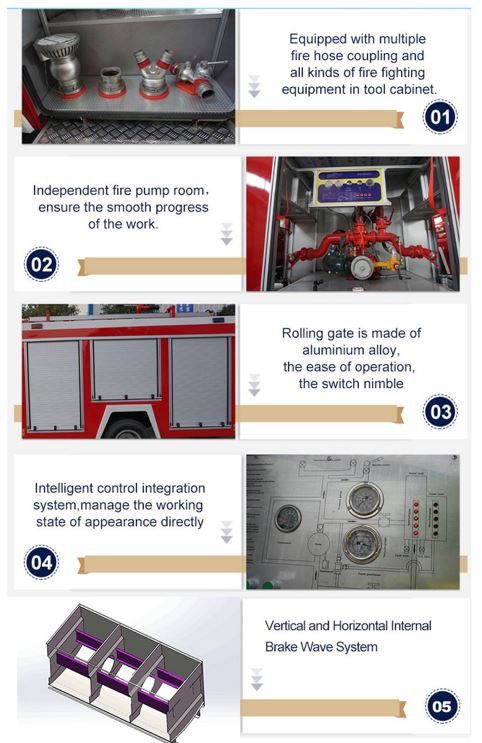

General Arrangement | Integral frame body, symmetrical on both sides. The two sides of the front and middle of the body are equipment compartments, the middle is a built-in independent water and liquid tanker, and the rear of the body is a pump room. |

Aluminum alloy rolling doors are installed on both sides of the compartments and the rear of the pump room; a catwalk ladder is installed on the right rear side of the fire truck. |

² COMPARTMENTS

Material | The main frame adopts high-quality steel frame structure, adopts carbon dioxide protection welding to complete the overall skeleton structure, and the outer decorative board, inner sealing board and floor adopt anodized flat aluminum plate.

|

Doors | The shutter doors on both sides and the rear of the pump room are made of aluminum alloy with a lock structure, which has good sealing and dustproof functions.

|

Pedal/ Step | The lower skirt of the rolling door is equipped with an outward-turning steel frame. The opening and closing of the pedal are double-fixed by a double tension spring hinge limit device. The aluminum alloy pattern cover structure pedal door has reliable safety performance.

|

² TANKER

Style | Built-in tank body, all-metal welded structure, with horizontal and vertical anti-wave plates inside, with manholes in the baffles, meet China Tanker product standards. The front and rear ends cover and anti-wave plate are equipped with trapezoidal folding ribs that can increase the strength, and the complete tank processed with anti-corrosion treatment. The tank body is connected to the frame with an integral subframe, and shock absorption pad equipped. |

Material | The water tank is welded by stainless steel material, welded by 3-5mm steel plate material (including tank connection pipe), bottom plate thickness 5mm, side plate thickness 4mm, top plate 3mm, anti-corrosion treatment, durable. |

Capacity | 5000 kg for water loading |

² FIRE CONTROLS

1) Fire Pump

Model Number | CB.10/30 | CB10/30

|

Type | Ordinary pressure centrifugal pumps | |

Flow capacity @ pressure | ||

Max. water suction depth | >7m | |

Priming device | Vacuum pump diversion | |

Water leading time | ≤35s |

2) Fire Package Control Dashboard

Display | Intelligent control; the buttons are all provided with Chinese signs; there are pipeline layout diagrams and instructions for operation and maintenance. The instrument panel is located above the water pump in the pump room, equipped with tachometer, vacuum gauge, water pressure gauge, level gauge and other instruments. |

3) Fire Monitor

Model | PL24 water foam dual use purpose |

PL24Water and foam dual purpose fire monitor |

Make | Shanghai Rongshen | |

Flow capacity | ||

Elevation angle | ≥70° | |

Depression angle | ≤-15° | |

Shooting range | Water: ≥55m | |

Rotation angle | ≥360° |

² PAINTING

Finish painting: Quality Paint | |

Color: R03 fire-fighting red for the cab and car body, light gray for the interior of the equipment room, aluminum color for aluminum rolling doors, black chassis frame, silver rims, white mudguards and bumpers. 3M reflective logos are pasted around the body. |

² ACCESSORIES

1) Equipment compartment assembly

- The inside of the equipment compartment is connected with high-strength aluminum profiles, and anodized flat aluminum plates are bonded.

According to the actual firefighting and fire operation procedures request ,use special fixtures that prevent corrosion, vibration, fall off, scratches, rotate, push or pull to fix all vehicle-mounted equipment. The equipment is reasonably arranged, compact, and firmly clamped. The marking is eye-catching, and any equipment can be used in the two actions, which can realize nearby pick-and-place, multi-person operation without interference. The main frame is welded by high-quality 20# steel carbon dioxide protection welding to ensure that the overall frame structure is high in strength, firm and reliable; the internal equipment box is made of high-strength aluminum alloy profiles to build the main frame, and the surface is anodized with small patterns. The surface of the aluminum alloy sheet and the corner aluminum edging process are processed to ensure the performance of the equipment box, while having the characteristics of beauty and lightness. |

2) Accessories list

No. | Description | Specification | Unit | Quantity | Remark |

1 | Electric siren | Amber | pcs | 1 | |

2 | Emergency rotation lamp | pcs | 1 | ||

3 | Fire Axe | 817mm | pcs | 1 | |

4 | Fire hook | Applied to climb | pcs | 1 | |

5 | Fireman ladder | Extension | pcs | 1 | |

6 | Medium pressure water gun | pcs | 1 | ||

7 | Fire Hose | 65mm-20m | reel | 4 | |

8 | Suction Hose | DN100(2m) | pcs | 4 | |

9 | Water-filter with guide rope | 100mm metal | pcs | 2 | |

10 | Suction pipe wrench | FS135 | pcs | 2 | |

11 | Fire Hydrant wrench | FBA800 | pcs | 2 |

3) Documents List

No. | Documents | Unit | Qty | Remark |

1 | Chassis Truck Operation Manual | set | 1 | Hard copy |

2 | Chassis Truck Maintenance Manual | set | 1 | Hard copy |

3 | Chassis Truck Certification | set | 1 | Hard copy |

4 | Engine Number Copy | set | 1 | Hard copy |

5 | Fire Truck Maintenance Manual | set | 1 | Hard copy |

6 | Parts List of Fire Truck | set | 1 | |

7 | Fire Truck Certificate | set | 1 | Hard copy |

8. | Commercial Invoice | set | 3 | Hard copy |

9. | Packing List | set | 3 | Hard copy |

10. | Sales Contract | set | 1 | Hard copy |

11 | Bill of Loading | set | 3 | Hard copy |

12 | Country of Origin | set | 1 | Hard copy |

Hot Tags: isuzu 700p fire water truck, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance