Capacity: 8CBM

Driving type: 4x2, LHD

Engine: 168hp Euro V

Size: 6810×2330×2550(mm)

G.V.W: 12490kg

Curb Weight: 4125kg

Full Payloading: 8000kg

Wheelbase: 3800mm

• This Truck Mounted Solid Waste Compactor is compatible with all chassis trucks, like ISUZU, SINOTRUK, DONGFENG, FOTON, etc.

• The volume of the box is 12CBM, with two-way compression, and the compression ratio is 1:2-1:3.

• Carriage plate cylinder mounted outside of the hooper area, keeping clear of the refuse loading area.

• Ergonomically designed for ease of operation and maintenance.

• Hopper volume: 1.5 m³ - 2 m³

• Tailgate sweeping cycle time: 25-30 sec.

• Discharging time: 40-60 sec.

Optional Features

• Button control ( Automatic compression cycle )

• Rearview camera, in-can monitor

• Automatic control

• 4m³ -8m³ skip container lifting system

The curved refuse body and the bottom plate are welded seamlessly, which eliminates the risk of leakage. High-strength manganese steel plate is used, and all reinforcements of the body shall be in the form of “U” shaped braces and full-seam welded on the body sheets, of thickness of 4.0 mm.

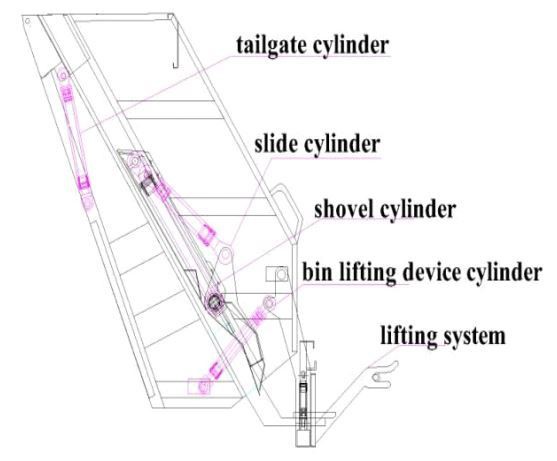

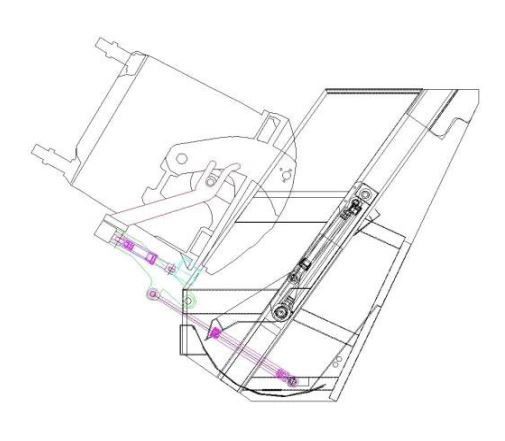

Collecting & Compacting

The loose garbage inside the hopper is taken into the body via a sweeper shovel being actuated by two double-acting hydraulic cylinders, and then after being pushed into the body by two double-acting sledge cylinders. The sledge cylinders have min. 24 tones pushing force. The compaction ratio (volumetric) varies between 3:1 to 6:1 according to the characteristic of the garbage.

Lifting

The tailgate raise is achieved by two double-acting hydraulic cylinders, which must be equipped with safety devices to prevent the tailgate from falling abruptly in the event of hydraulic failure or hose burst.

Hopper

The loose garbage capacity of the loading hopper is around 1,5 m³ with the self-cleaning ability during discharge.

Locking

Hydraulic locking by means of reverse action of two hydraulic tailgate lifting cylinders also prevents the leakage of the wastewater when the truck bounces due to road conditions.

Ejector Panel

A totally automatic hydraulic system allows the panel to advance forward as garbage is packed against it. Material 6mm thickness.

Rail

The ejector panel shall glide on a Standard NPU 120mm profile, centered by means of friction resist polyamide bases. The ejector panel shall slide forward and rear over these rails thanks to a set of Polyamide wear plates in four points.

Operation & Control

The system is controlled from the PLC control box, which enables, start, stop, 1-cycle, continuous cycles, and rescue activities. Tailgate and ejector controls are in front of the body. All devices for loading control are mounted on the tailgate right side, and all are manual control for safety purposes. Compaction is controlled electrically via pushbuttons, and manually in case. There is an emergency stop button on each of side the truck on the control panel.

All the hydraulic cylinders are double-acting cylinders. The pipes on hydraulic cylinders are of Italy origin. Pipes are to be made of honed drawn steel pipe, and cylinder miles are ground and chrome coated against corrosion. The dimensions of cylinders are designed to accomplish the stipulated cycle times and compaction ratio.

Engine | |

Make/Model | Cummins/ISF3.8S4R168 |

Type | Diesel Engine |

Engine System | 4 Stroke, High Pressure Common Rail, Inter-cooling Turbo-Charged, 4 Cylinders |

Output Power@ speed | 168hp@2600rpm |

Displacement | 3.76L |

Max. torque @ Speed | 600N.m@1300-1700rpm |

Emission standard | Euro 6 |

Transmission | |

Gears | 6F+1R |

Operation | Manual |

Cabin | |

Type | Steel construction, Single Row, Flat |

Passenger No. | 3 |

Body and Compaction System | |

Capacity | 8CBM |

Material | Weather-resistant steel, high corrosion resistance |

Design | Sealed leakage proof |

Compaction Ratio | 1:2 - 1:3 |

Containers Lifting Devices | High capacity articulated lifter works in a minimum of two stages by four double effects hydraulic cylinders to ensure the lifting and lowering of containers smoothly. Lifting weight capacity not less than 800 kg. |

Control System | Equipped with three sets of automatic, manual control, and wireless remote control modes, it can control the operation of the garbage truck in the driver’s cab, the middle of the garbage, and the rear of the garbage. |

Hot Tags: Mounted Solid Waste Compactor - CSCTRUCK