Model Number: CSC5110ZYSQL

Garbage Container Capacity: 8CBM

Garbage Compression Density (t/m3): 0.6~0.8

Max. Compression Force (kN): 210

Chassis brand: ISUZU

Engine horsepower: 190HP

Rear Loaders Refuse Equipment 8CBM

BRIEF

Model Number: CSC5110ZYSQL

Garbage Container Capacity: 8CBM

Garbage Compression Density (t/m3): 0.6~0.8

Max. Compression Force (kN): 210

Chassis brand: ISUZU

Engine horsepower: 190HP

INTRODUCTION

The CSC high-performance garbage compactor truck is a garbage compression vehicle with high compression rate, large loading capacity, fast operation efficiency, and low noise. Garbage thrown into the hopper is first crushed by the press plate and then compressed and compacted by the ejection plate inside the body. Collected garbage can be easily discharged from the body by operation of the ejection plate. The refuse compactor can comprehensively solve the common problems such as small capacity, small compression force, and low operating efficiency of compression vehicles. The advanced level of features for loading, compacting and transportation are sure to meet clients’ need. CSC has developed over decades of experience for truck manufacturing.

FEATURES

● CSC compactor truck uses a high-strength U-shaped integrally formed truss slot as the guide rail of the garbage pushing plate, which has strong compression capacity and good deformation resistance.

● The main components are all made of high-strength weather-resistant steel plate.

● The overall frame adopts structural design, which makes the shape simple and with good-appearance, and increases the effective garbage container’s volume. Its structure has outstanding performance and strong impact resistance.

● The sliding block of the push plate is made of high wear resistance material with long service life.

● It is equipped with sewer tank, combined with a diversion type sewage collection device, which can divert the sewage that leaks between the hopper and the hopper due to the failure of the sealing strip to a special sewage collection tank. It prevents effectively secondary pollution caused by sewage leakage.

● CSC compactor truck’s hydraulic system adopts European popular double-pump and double oil-way, type consists with amphibious multi-way valve, which are both control ways: pneumatic-electronic and manual operation. Its special cartridge valve blocks, came from Europe also, with two-way compression function, which material is alloy cast iron, and its surface of valve spool treat with nitrogen, has a stable reversing, motor-driven and manual operation.

● CSC’s control system’s motor-driven manual operation is convenient and efficient. When truck is working, chassis’ engine has synchronous acceleration, productivity and oil-saving effect.

● Various mechanical turn-over devices are optional.

● It meets well shapes, reasonable weight, and longer working life requirements after designed optimally.

● Precompression rail: Rail is one of the main parts of precompression, precision machining rail and high-strength nylon slide constitute the most advanced skateboarding. Its groove width, length straightness well & working surface well. Rail has good rigidity, high strength, and slide contacting surface can reach more, making slide running stable.

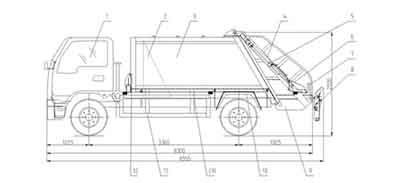

Structure drawing

| 1: chassis | 2: box body |

| 3: discharging mechanism | 4: hopper | |

| 5: lift mechanism | 6: compression mechanism | |

| 7: flex mechanism | 8: charger mechanism | |

| 9: hydraulic system | ||

Structure Components

● Compressor bin: material is strengthening beam and high-strength manganese, while its side panel’s technology is one take molding process; used for storage garbage, and in which equipped with shoveling assembly

● Hydraulic system assembly: included storage tank, oil pump, oil filter, multi-way valve, oil pipes and oil cylinders

● Shoveling assembly: material is rectangular pipe skeleton and high-strength manganese; included shoveling cylinder, shoveling; used for pushing garbage out of compressor bin when truck discharging

● Hopper assembly: included lift hydraulic cylinders and hopper, and under hopper, there equipped with one waste water tanker to prevent dirty water leakage; used for as rear cover of compressor bin and storage garbage temporarily

● Skateboard assembly: mounted on top of hopper; used for up and down movement

● Scraper assembly: equipped on skateboard assembly which can open and scrap; used for scrap garbage in hopper and delivery garbage into compressor bin through skateboard lifted

● Hanging garbage bin barrel assembly: used for delivering garbage in ground garbage bin into hopper through hanging barrel flip bracket

Parts of Structure

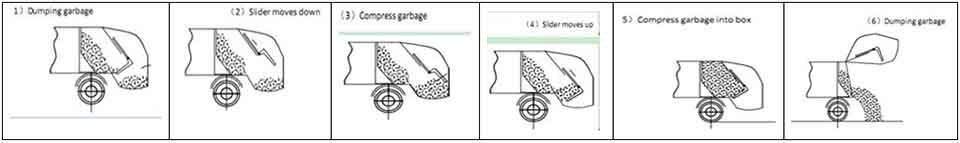

Working principle

Production Process

Specification

General | |

Truck Model | CSC5110ZYSQL |

Chassis Brand | ISUZU |

Chassis Model | QL1100 |

Driving type | LHD |

GVW | 11000kg |

Curb weight | 6800kg |

Axle No. | 2 |

Wheelbase | 3815mm |

Approach / Departure angle | 17 / 13° |

Tire No. | 6+1spare tire |

Tire Specs. | 235/75R17.5 8.25R20 |

Max. Speed | 110km/h |

Front axle capacity | 3500kg |

Rear axle capacity | 7050kg |

Springs | 8/10+6 |

Front wheel trace | 1680mm |

Rear wheel trace | 1650mm |

Engine | |

Brand | ISUZU |

Model | 4HK1-TCG40 |

Horsepower | 190HP |

Displacement | 5193ml |

Emissions standard | Euro4 |

Max. Torque | 510N.m |

Max. rotated speed | 1699rpm |

Type | 4 Stroke, High Pressure Common Rail, Inter-cooling Turbo-Charged, 4 Cylinders |

Transmission | |

Brand | ISUZU |

Model | MLD |

Forward/reverse | 6F/1R |

Type | Manual |

Cab | |

Type | Single-Row Cab with Air Conditioner |

Color | Usually white |

Garbage compactor upper structure | |

Garbage container volume | 8CBM |

Garbage container material | 16Mn Manganese steel |

Hopper material | Q345 stainless steel |

Hydraulic system pressure | 18MPa |

Garbage Compression Density | 0.6~0.8t/m3 |

Feeding cycle time | ≤12s |

Unloading cycle time | ≤40s |

PLC brand | Germany Siemens |

Hydraulic cylinder control way | Manual mechanical control and Electrical auto control |

Unloading cylinder | 1set Control push shovel’s push off and retraction |

Lifting cylinder | 2sets Control recompression’s lifting and down |

Up & down cylinder | 2sets Control slider’s moving up and down |

Scraper cylinder | 2sets Control scraper’s retraction and strengthen |

Hopper cylinder | 2ets control hopper’s open and close |

Safety valve | Equipped on tailgate to prevent sudden fall during maintenance |

Hot Tags: rear loaders refuse equipment 8cbm, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance