•SINOTRUK 4×2 Truck Chassis

•Capacity 8000L Sewer Tank

•Italy MORO PA70A Pump

•MC11.39-30 Euro 3 Engine

•Vacuum Suction Depth 8m

•Pump Capacity 720m3/hour

BRIEF

The Vacuum Truck, a specialized vehicle engineered for the collection and transportation of sewage and sludge, represents a crucial component in modern sanitation infrastructure. Mounted on the robust HOHAN 4x2 truck chassis, this Vacuum Sewer unit embodies efficiency, durability, and functionality.

At its core, the Vacuum Sewer system integrates seamlessly with the truck chassis, comprising a subframe meticulously connected to the chassis to ensure stability and structural integrity during operation. This foundational design element not only enhances the truck's performance but also facilitates the seamless integration of essential components.

Central to the Vacuum Truck's operation is its cylindrical tank, strategically positioned atop the subframe. Crafted from high-quality materials, the tank boasts a robust construction capable of withstanding the rigors of sewage and sludge collection. Its sizable capacity enables the efficient containment and transportation of waste materials, optimizing operational efficiency and reducing downtime.

Facilitating the loading and unloading process, the Vacuum Truck features a hydraulically opening full-diameter tailgate. This innovative design element streamlines the disposal process, allowing for swift and hassle-free discharge of collected waste materials. Moreover, the tailgate's hydraulically powered mechanism ensures reliability and ease of use, further enhancing the operator's experience.

Integral to the Vacuum Truck's functionality is its vacuum system, powered by the Power Take-Off (PTO). Leveraging the truck's mechanical power, the vacuum system utilizes suction to extract sewage and sludge from designated collection points, ensuring thorough and efficient waste removal. This advanced system not only simplifies the collection process but also minimizes environmental impact by effectively containing and transporting waste materials.

In summary, the Vacuum Truck represents a pinnacle of engineering excellence, combining cutting-edge design with robust construction to deliver unparalleled performance in sewage and sludge management. With its innovative features and reliable operation, this specialized vehicle serves as a cornerstone of modern sanitation infrastructure, facilitating the maintenance of clean and hygienic environments for communities worldwide.

Vacuum Truck Map

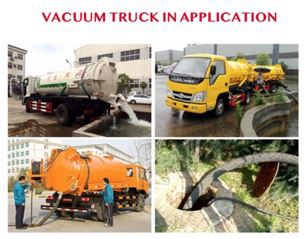

Application:

The purpose of the vacuum truck is to clean cesspools by suction and transport fecal liquids to disposal sites. Its specialized components include a tank, powered vacuum pump, signal safety device, suction hose with a receiving manhole, pipeline control valves, platforms, and supplementary electrical equipment. Tank filling occurs through vacuum suction generated by the pump, gravity discharge from the tank, or air pressure provided by the vacuum pump.

Features

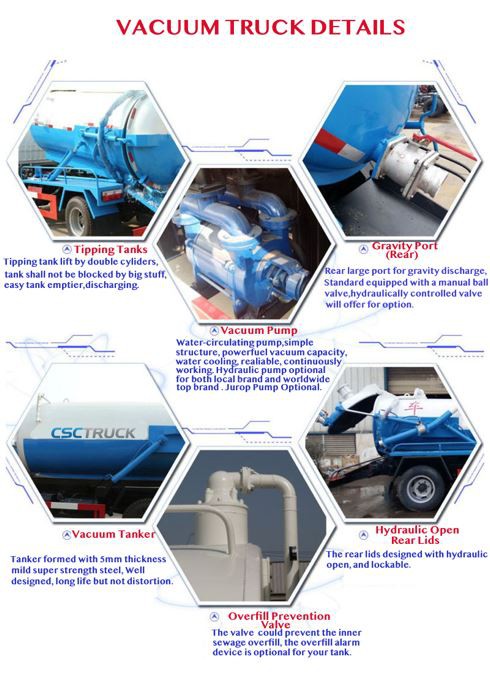

Hydraulic Open Rear Lid

1) Stainless Steel Discharge Valve: 4-inch Diameter, Male Flange Connection

2) Tank Skirt at Rear: Minimizes Secondary Pollution Risks

3) Durable Wing Clamps: Built for Heavy-Duty Applications

4) Inspection Window: Allows for Easy Monitoring and Checking

Tipping Tank

1) Dual-Action Cylinders Operate on Both Sides, Spool Valve Body Controls the Rear Door, Hoist, and Vibrator.

2) Transparent Acrylic Sight Glass

3) Overfill Prevention Release Valve

4) Ascend Using a Ladder with 25mm Tubular Handrails

5) Carrier for Spare Tires

1) Large stainless steel suction tubes, elbows, and valve fittings are offered.

2) Steel hose tray and side marker lamps with check functionality.

3) Dependable double-acting cylinders sourced from top-quality Chinese suppliers.

4) Comprehensive pump workstation with gauges and controls provided.

5) Robust tank pads designed for heavy-duty usage.

6) Various sizes of suction hoses (2", 2.5", 3") are available for a seamless connection.

Fitting and Components

SPECIFICATION

|

1) CHASSIS BRAND/MODEL |

HOHAN/ ZZ1185K5113C1 |

Wheel Drive |

4×2 |

|

|

2) ENGINE |

Model/Make |

MC07.28-30/SINOTRUK |

||

|

Type |

4 cycle & water cooled, 6 in line and replaceable dry type liner |

|||

|

Displacement |

6.87L |

|||

|

Fuel Type |

Diesel |

|||

|

Net Power Output / Speed |

206kw(280hp) /2300rpm |

|||

|

Torque/ Output / Speed |

1100N.m/1200-1800rpm |

|||

|

Bore × Stroke |

108×125mm |

|||

|

Weight |

640kg |

|||

|

Compression Ratio |

16.5:1 |

|||

|

Aspiration |

Turbo-charged |

|||

|

Engine Lubrications |

Engine lubrication shall be of the full force feed type and driven by gear. Oil filtration shall be preferably with two replaceable cartridge filters. An oil cooler shall be incorporated in the lubrication system. |

|||

|

Certified Engine Data |

showing net power, torque, and specific fuel consumption curves at governed rpm at sea level and 2500 m elevation. |

|||

|

3) FUEL SYSTEM |

Fuel Tank Material |

repairable steel and properly ventilated |

||

|

Full Tank Capacity |

300L |

|||

|

Filler Cap |

Lockable |

|||

|

Injection Pump |

Electrical control, high-pressure common rail |

|||

|

Injectors |

accessible, interchangeable, and readily removable |

|||

|

Fuel Filters |

two in series with water & sediment trap. Filter readily removable for quick maintenance. |

|||

|

Oil Sump |

Made from repairable steel. |

|||

|

4) COOLING SYSTEM |

Medium |

Water coolant |

||

|

Upper and lower channels/tank |

Made from aluminum |

|||

|

Properly mounted to withstand shocks and strains likely to be encountered in operation. |

||||

|

Cooling Fan |

Silicone oil cooling fan |

|||

|

Thermostat |

Tropical type 71℃ thermostat |

|||

|

Warning device |

Audible & visual |

|||

|

5) AIR INTAKE SYSTEM |

Heavy duty, dry type fitted with pre-cleaner cyclone type |

|||

|

6) EXHAUST SYSTEM |

Emission Standard |

Euro 3 |

||

|

Sound Level |

Sound level <85dm |

|||

|

7) ELECTRICAL |

Battery |

Heavy duty, 2×12V, 180 Ah at 20 hours rating. |

||

|

Horns |

electrical |

|||

|

Lighting |

Two adjustable headlights with high and low beams, two parking lights, two combination stop, tail, and direction lights, cabin interior lights, backup lights with automatically activated warning devices, instrument panel light, two reflectors and clearance light, plate number light, hazard flasher any other light required by ICE standard motor vehicle safety regulation. |

|||

|

Starter Motor Capacity |

5.5kw |

|||

|

Alternator Output |

24V |

|||

|

8) AIR SUPPLY SYSTEM |

Compressor Capacity |

0.85MPA 636(cc/r) |

||

|

Warning Device |

Audible and visible |

|||

|

Air Reserve Tank Capacity |

40L |

|||

|

Valves |

Heavy duty |

|||

|

Connection and Coupling |

Heavy duty |

|||

|

Airline |

As SINOTRUK standard from air pipe to air filter to air compressor to engine |

|||

|

9) STEERING |

Model/Make |

D50 power steering/ SINOTRUK |

||

|

Position |

Left-hand installed steering |

|||

|

Power Assisted |

Hydraulic power-assisted steering system |

|||

|

Power Steering Pump |

Gear driven directly mounted to the engine |

|||

|

10) TRANSMISSION |

Model/Make |

DC7J100TC/ Dachi |

||

|

Type |

Heavy-duty manual, constant & synchromesh |

|||

|

Gear Numbers |

7 speeds forward and one reverse speed (7×1) |

|||

|

11) AXLE |

Front Axle Model/Make |

H153/SINOTRUK |

||

|

Front Axle Type |

Heavy duty "I – beam'' construction mounted on heavy-duty springs with heavy-duty shock absorber, spindles, kingpins, trust bearings, and wheel bearings in properly sized and matched with this rating. |

|||

|

Front Axle Rating |

6 ton |

|||

|

Rear Axle Model/Make |

153/SINOTRUK |

|||

|

Rear Axle Type |

heavy-duty, full–floating |

|||

|

Rear Axle Rating |

10 ton |

|||

|

12) SUSPENSION |

Front |

Heavy duty semi-elliptical front spring 9 no. leaf spring |

||

|

Rear |

Heavy duty rear spring 12 no. leaf spring |

|||

|

13) BRAKE |

Type |

Pneumatically operated |

||

|

Service Brake |

All-wheel dual system. Pneumatically operated, the wheels are equipped with a drum and manually adjustable type brake shoe. Front and rear Drum type. |

|||

|

Parking Brake |

To be a mechanical spring-operated type acting on the rear axle, capable of holding the fully loaded truck (front or reverse) on a 20% gradient. |

|||

|

Engine Brake |

Manufactures standard pneumatically operated engine brake with an operating switch located within the driver's reach to be installed. |

|||

|

Brake Performance |

Service brakes are capable of controlling and holding the fully loaded truck on a 20% grade. It is consistently bringing the fully loaded truck to a complete stop within 12 meters from a speed of 32 km/hr on a hard, dry-level road free from loose material |

|||

|

14) WHEEL & TIRES |

Wheels |

Single front wheel, dual rear wheels |

||

|

Rims |

7.5 |

|||

|

Tires |

10.00R20,18PR tube type, and heavy-duty type. A spare tire, assembled with a rim installed on a strong lockable carrier. |

|||

|

Spare Tire |

1 no. same size with truck wheels and tires |

|||

|

15) CABIN |

Model |

H77L |

||

|

Type |

Forward tilting |

|||

|

Construction |

all steel construction |

|||

|

Instrument and Controls |

All gauges and meters are to be indicated in metric unit |

|||

|

No. of Seats |

1 driver plus two passengers |

|||

|

Driver Seats |

Adjustable & separate from passengers' seat |

|||

|

Passenger Seat |

Fixed |

|||

|

Seat Belt |

Equipped (for driver and passenger) |

|||

|

Mud Flap |

Equipped |

|||

|

Safety Equipment |

Fire extinguisher 2kg |

|||

|

Cab Mounting Steps |

Equipped |

|||

|

Hand Holds Internal |

one grab handle at the driver's side & one at the passenger side shall be provided |

|||

|

Audio System |

FM/AM, SW, 4 Band radio MP3, two speakers & antenna |

|||

|

16) CHASSIS |

Frame |

Heavy-duty construction and capable of withstanding the strain of rigorous on and off-road surface |

||

|

Bumper |

Heavy-duty front and rear steel bumpers be installed |

|||

|

Towing Device |

Front towing device and rear trailer coupling be fitted on the chassis frame |

|||

|

17) CARGO BODY |

Ground Clearance |

280mm |

||

|

Wheelbase |

4500mm |

|||

|

Overall Length |

7200mm |

|||

|

Overall Width |

2496mm |

|||

|

Overall Height |

3290mm |

|||

|

Rear Overhang |

1300mm |

|||

|

Subframe |

A separate chassis shall be used for mounting the sewage tank. |

|||

|

18) PERFORMANCE |

Turning Radius |

7m |

||

|

Grade Ability |

35% (20-30km/h) |

|||

|

Maximum Speed |

95km/h |

|||

|

Fuel Consumption |

198g/kW.h |

|||

|

19) EMPTIER TANK |

Material |

Mild Steel, Grade Q235, Tensile δ5/% Yield Strength 235Mpa, Thickness 6mm Tanker Size: Diameter 1640 mm |

||

|

Tank Style |

Cylindrical type, equipped with splash walls/ baffle plates and reinforced around the circumference. Two heavy-duty hinges support the tank's rear door. |

|||

|

Exterior |

Sanded before spray painting and spray painted with two coats of superior quality anti-corrosive primer and two coats of enamel metal paint |

|||

|

Interior |

Surface preparation and finish of Tank's Interior with two coats of Epoxy coating to resist corrosion (Manufacturer warrantee that the tank's Interior resists aggressive wastewater) |

|||

|

Filling Level Indicator |

2 nos Indicator mark on the tank for maximum and minimum level of Acrylic Sight Glass furnished |

|||

|

Loading & Unloading |

· Height from ground to suction hose 1.4 m · Tailgate tightly locked, two suitably dimensioned double-acting hydraulic cylinders affect the raising and lowering of the door. The door be raised through a minimum angle of 80° to the vertical. Locking and sealing of the rear door be done by hand wheel-operated bolts, of a robust design located circumferentially on the tank's rear end of the shell. · Provided Vacuum limiting valve and drain-off valve · Outlet from the tank provided with a quick connect coupling interface. |

|||

|

20) VACCUM PUMP |

Model/Make |

PM80A /Italy MORO |

||

|

Type |

Heavy duty Rotary blade/vane type |

|||

|

Cooled |

Air |

|||

|

Free Air Flow |

12000 liters/ min (720m3/hour) |

|||

|

Continuous Duty Vacuum |

80%, 23.6 in Hg |

|||

|

Max Vacuum |

95%, 28 in Hg |

|||

|

Max. Operating Absolute Pressure |

3 bar, |

|||

|

Power required at max vacuum |

14kw, 20.4hp |

|||

|

Power required at max Pressure |

34kw, 46.2hp |

|||

|

Oil tank capacity |

3.7liters |

|||

|

Max. Speed |

1400rpm |

|||

|

Working Speed |

1000-1100rpm |

|||

|

Vacuum Suction Depth |

8m |

|||

|

Performance Curve |

|

|||

|

Overflowing |

Air pump to safeguard pump from overflowing Sludge tank between the air pump and the tank. |

|||

|

Installation |

The location of the pump installed is very accessible for routine and overhaul maintenance. it is installed by the left side of the emptier tank. |

|||

|

Control |

Four-way-cock for suction and pressure manually controlled, safety valve for maintenance of the pressure. Adjusted pressure 0.5 bar. |

|||

|

Safety Device |

Safety devices for overflow protection of the vacuum pump:

1, Primary shut-off valve 2, Secondary shut-off valve 3, Air safety filter, 4, Vacuum relief valve 5, Pressure relief valve 6, Vacuum pressure gauge 7, Silencer (Oil catch muffler) |

|||

|

21) SUCTION HOSE |

Material |

PVC along with quick connect coupling |

||

|

Type |

Flexible, lightweight heavy-duty, reinforced, oil resistant. The suction hose withstands 90% vacuum. |

|||

|

Diameter |

Internal 76-80mm,3inch |

|||

|

Length |

3m left and right side |

|||

|

Hose Tray |

Two hose trays each one on the left and right, made of galvanized steel, Lockable storage compartments for hoses and other equipment along both sides of the tank |

|||

|

22) COLOR |

Light blue is the manufacturer's standard |

|||

|

23) INSTRUMENTATION |

Temperature Gauge |

Manufacturer standard Provided |

||

|

Pressure Gauge |

Manufacturer standard Provided |

|||

|

Level Control |

Manufacturer standard Provided |

|||

|

24) WATER TANK |

Capacity |

25L |

||

|

Material |

plastic with soap dispenser |

|||

|

Purpose/Application |

for hand cleaning |

|||

Hot Tags: vacuum trucks with 8cbm tank capacity, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance