Chassis Make: FOTON/AUMAN EST-M G.V.W: 18-20tons Engine Make/Horsepower/displacement: Weichai/270hp/9.726L Wheelbase: 4600mm Transmismsion Make/Gears: Shanxi FAST / 9F+1R Tire specs.:11.00R20 Water Tank Capacity: 10,000Liters / 10CBM Water Tank Material: 304 2B

Attention:

These Foton Stainless Steel Water trucks are only available for Limited Time with Limited Amounts in Stock! ONLY LIMITED OPPORTUNITIES! Incredible Low Price with Premium Quality! Contact us now! Earlier contact or Nothing!

WHY CHOOSE CSCTRUCK STAINLESS STEEL WATER TRUCK

FOTON AUMAN EST is produced by technologies of Daimler-Benz and U.S. Cummins and partnered with the world's automotive industry leaders including German ZF and WABCOM

Used for transporting drinking water/potable water and dust-control in places with high corrosive environments, such as power plants, near the sea. ect

Completely custom built to customer's specifications

Produced for high-quality, durability, and excellent performance

Fast draw from any water source

A powerful 270hp of the heavy-duty truck is adopted to handle all types of terrain

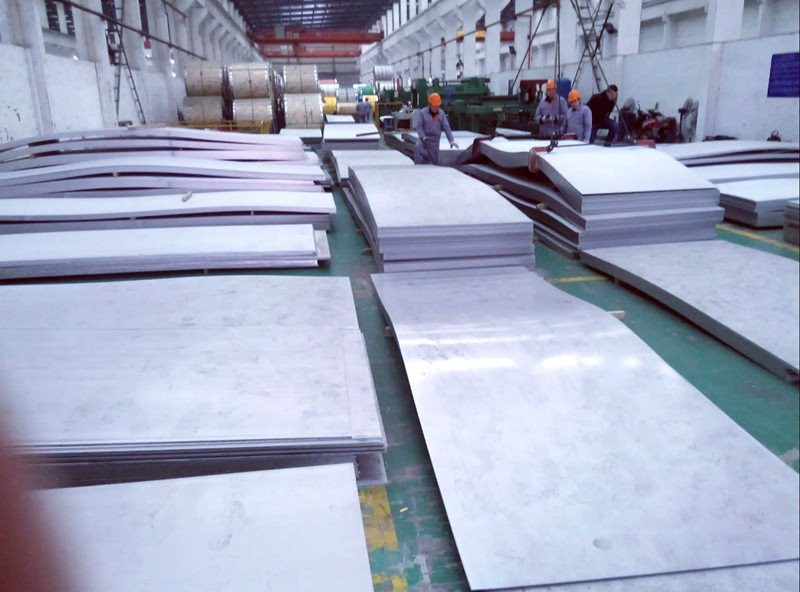

304-2B stainless steel has outstanding corrosion resistance, stronger surface gloss, and easy grinding.

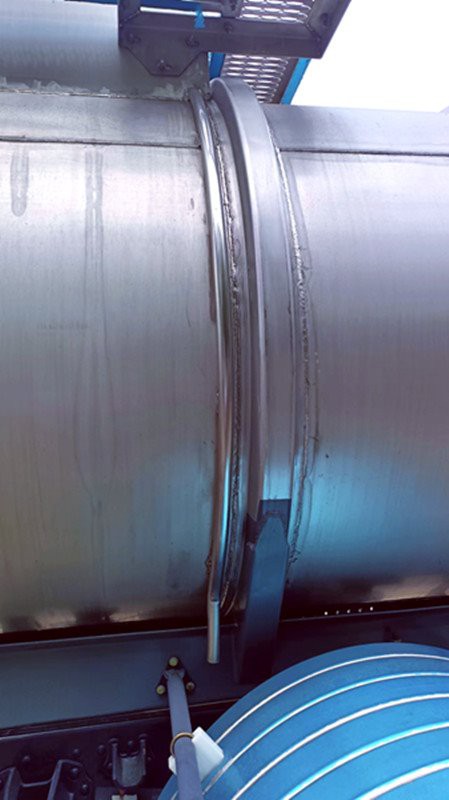

Round shape tanker tested of hydrostatic pressure to 5psi(35kpa)

A dished head is formed by one-time hydraulic inflation with symmetrical in appearance and beautiful in shape, which can effectively buffer the impact of the liquid on the head, the impact resistance is much higher than that of a flat & conical head & easy to clean

The uniquely designed tank rib ensures the firmness, strength, and integrity of the tank, and effectively prevents the welding joint of the tank from cracking and distorting.

The hydraulic convex anti-wave plate is fully welded with the tank with an arc-shaped flushing edge to make the tank cleaned without residue.

Stainless steel, 400mm wide, with nonskid rungs and lateral handles, mounted at right middle of the tanker.

Carbon steel, basket type, located behind the landing gear

SPECIFICATION

A. TANK BARREL | ||

1. Tank Profile | Round shape | |

2. Test pressure | Hydrostatic test to5 psi (35 Kpa) on each compartment. | |

3. Working pressure | Atmospheric. | |

4. Capacity | 10000L plus 3~5% ullage. | |

5. Compartments | Single compartment. | |

6. Interior weld finish | Not polished or grinded (W-0). | |

7. Exterior weld finish | Not polished or grinded (W-0). | |

8. Shell material | Stainless steel 304 2B. | |

a) Top | 3.7mm nominal. | |

b) Sides | 3.7mm nominal. | |

c) Bottom | 3.7mm nominal. | |

9. End Plate | Stainless steel 304 2B, 3.7mm nominal. | |

All single heads dished and flanged. | ||

10. Baffle / Surge Heads | Stainless steel 304 2B, 3.7mm nominal. | |

Dished with flap. | ||

1 pcs. | ||

11. Spill molding and rollover protection | Stainless steel around the dome with drain hose. | |

12. Outer rings | 304-2B stainless steel, 60mm height, 3mm nominal, continuously welded. | |

13. Frame | Carbon steel independent. | |

14. Loaders and brackets | Carbon steel. | |

B. TANK FITTINGS AND PIPING | ||

1. Manholes | 20" diameter with 6 stainless steel wing nuts, located at the top center | |

2. Pressure Vacuum Vent | Two per compartment. 6~12 kPa pressure, 2~4 kPa vacuum. | |

3. Discharge system | 3” diameter discharge with 3" diameter butterfly valve, 3" stainless steel male Camlock coupling, and quick cap, located at the back of the tank. | |

C. ACCESSORIES | ||

1. Ladder | Stainless steel, 400mm wide, with non-skid rungs and lateral handles, mounted at right middle of the tanker. | |

2. Walkway | Extruded aluminum around the dome. | |

3. Hose Carries | 1 no, hose carrier (round tubes) to fit Ø159 x 6meter (236") hose close type complete with brackets to be installed at the right side. | |

4. Hose | Firemen type flexible discharge hoses, 30m 3" for discharge. and flexible plastics suction hoses, 5.9m 3" for suction, 3" female camlock coupling at both ends. | |

5. Rear Bumper | Aluminum member to accommodate light assembly and number plate to cover the full width of the tank. | |

Steel bumper with a ground clearance of 500mm approx. | ||

6. Mudguard | Aluminum over suspension and the upper coupler. | |

Mud flaps rigid plastic at the rear. | ||

7. Lights & Wiring | 24V. ISO 1185 7-pin socket. | |

Harness: oil and vapor proof cable. | ||

Side: | ||

Mark lamp 3Pcs/side, LED. | ||

Reflector 3Pcs/side | ||

Turning lamp 1Pcs/side, LED. | ||

Rear Bump: | ||

Reverse lamp R-L 2Pcs. | ||

Turning lamp R-L 2Pcs. | ||

Brake lamp R-L 2Pcs. | ||

Register plate light | ||

Rear top: YES. | ||

Brand of Wiring: Phillips | ||

8. Connector Box | At the center in the front dished | |

9. Sticker | 50mm wide red-white reflective sticker, mounted at both sides and rear bumper. 50mm | |

10. Fire Extinguisher | 8kg, 2Pcs. | |

Carbon steel extinguisher holder is located on the landing gear on the curbside. | ||

11. Drains hose | water drains hose 2", installed at the back of spill molding | |

12. Spare wheel bracket | 1set | |

Carbon steel, basket type, located behind the landing gear. | ||

13. Painting | Polyurethane medium aluminum gray, applied over epoxy primer on carbon steel elements | |

Hot Tags: foton 10,000liters stainless steel water tanker truck, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance