Model No.: CSCMDT008.

Milk Tank Volume: 8000 Liters.

Overall Dimensions(LxWxH): 6,930x2,280x2,800mm.

Chassis Brand: HOWO.

Drive Type: 4x2.

Wheelbase: 3,800mm.

Engine Model: YN4102QBZL.

Engine Power: 116HP.

Emission Standard: Euro 2.

Tank Material: Stainless steel 304-2B.

BRIEF

The HOWO 8000-liter milk delivery truck, produced by CSCTRUCK, is a reliable and efficient vehicle designed for the safe and hygienic transport of milk. Built on the durable HOWO chassis, this truck features a 4x2 drive type, ensuring stability and maneuverability in various road conditions.

At the heart of the tank truck is the YN4102QBZL engine, delivering 116HP of power. Compliant with the Euro 2 emission standard, the engine provides an eco-friendly solution while maintaining robust performance, making it suitable for both urban and rural milk transportation.

The truck's milk tank has a capacity of 8,000 liters, catering to the needs of medium-to large-scale dairy operations. The tank is constructed from stainless steel 304-2B, known for its exceptional corrosion resistance, strength, and food-grade quality. This ensures the transported milk remains uncontaminated and fresh throughout the journey.

Designed with practicality and efficiency, the HOWO milk delivery truck offers a perfect combination of durability, hygiene, and functionality. Its specifications make it an ideal choice for dairy companies seeking reliable transportation for their products. The vehicle balances affordability and operational effectiveness, ensuring high-quality performance in demanding conditions.

FEATURES

1. Tank Capacity and Material: Equipped with an 8000-liter milk tank made of durable stainless steel 304-2B, ensuring hygiene and corrosion resistance for food-grade transport.

2. Chassis and Drive Type: Built on a robust HOWO chassis with a reliable 4x2 drive configuration, it is suitable for efficient milk delivery in diverse terrains.

3. Engine Specifications: Powered by the YN4102QBZL engine, delivering 116HP of engine power with a fuel-efficient design.

4. Emission Compliance: Meets the Euro 2 emission standard, balancing performance with basic environmental compliance.

5. Manufacturer Excellence: It is produced by CSCTRUCK, a renowned manufacturer specializing in purpose-built trucks, which ensures quality and reliability in milk transport operations.

SPECIFICATION

|

Milk Truck Make & Model |

HOWO/ MT08ZZ116L2 |

|

Function |

For milk transporting |

|

Truck Make & Series |

HOWO/ZZ1107 |

|

Producing Year |

2024 |

|

Overall Dimensions(LxWxH) |

6,930x2,280x2,800(mm)(approx.) |

|

Curb Weight |

4,500kg(approx.) |

|

Drive Type |

4x2, LHD |

|

Wheelbase |

3,800mm |

|

Axle loading |

2.7T/7.2T |

|

Engine |

YN4102QBZL / 3.76L / Euro2 / 116HP / 4 cylinders |

|

Transmission |

WLY6TS55C, 6F+1R / Manual |

|

Cab |

HOWO / day cab/ white color/ with air conditioner |

|

Fuel tank |

120L / iron |

|

Tire No. / Specs. |

8.25R16 |

|

Tank Capacity |

8,000 Liters |

|

Tank shape |

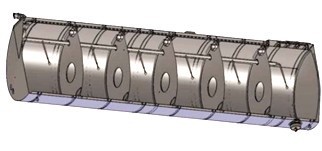

The car tank is integrated, and the front and rear of the outer head are spherical. Divided into 2 compartments. |

|

Tank inner tank: Material: stainless steel 304-2B |

Thickness 3mm; tank body reinforcement is made of double-folded U-shaped 3mm high-strength steel; sub-beam and reinforcement are connected to enhance the consistency of inner tank strength and avoid cooling loss; argon arc automatic welding process; |

|

End-cap of Tanker Material |

stainless steel 304-2B. Spherical head |

|

Anti-wave board in the tank |

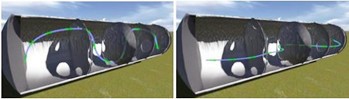

stainless steel 304-2B. Spherical, the manholes of the anti-wave board are staggered, which is convenient for milk to form an "S"-shaped circulation in the tank; the diameter of the manhole of the anti-wave board is ∮550mm |

|

Manhole |

1pc pressure manhole, diameter ∮ 450mm, the platform is equipped with a liquid accumulation tank for directional drainage. |

|

Breathing hole |

2-way ventilation pressure breathing hole, ∮108mm |

|

Pipe & Valve of discharging milk |

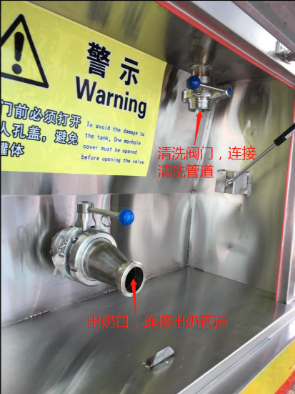

The milk discharge pipe is SUS304 food grade stainless steel with φ63; the milk discharge valve is a butterfly valve with a diameter of φ63 to φ50, and the diameter is changed by horseshoe diameter. The milk discharge port is located in the tail operation box. |

|

Cleaning Pipeline |

The inlet of the cleaning pipeline is φ50 and the outlet of the branch is φ40. The parallel mode is adopted; the spray effect of rotating cleaning is 360°, there is no dead angle for cleaning, and each compartment can be independently cleaned. |

|

Insulation layer |

Polyurethane overall foaming, thickness 80mm, foaming density 40-50KG/m³; |

|

Shell Plate |

Stainless steel 304-2B. Thickness 1.0mm |

|

Thermometer |

The tank is equipped with 1 milk temperature sensor, and the digital thermometer is installed in the cab. |

|

Escalator outside the tank |

Rear stainless steel anti-skid escalator |

|

Tank top platform |

Stainless steel skid plate |

|

Tank top guardrail |

Fixed stainless steel guardrail |

|

Tank stairs |

Stainless steel movable ladder |

Advantages of HOWO Milk TRUCK

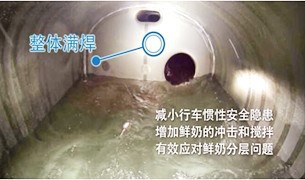

Low center of gravity oval tank structure: The fresh milk truck adopts a low center of gravity ellipse tank cross-sectional structure design with a more complex production process. It effectively reduces the height of the center of gravity of the vehicle, maximally prevents the vehicle from turning and rolling over, and enhances the driving safety of the tanker. The inner tank of the tank is welded on one side and both sides by a fully automatic controlled argon arc welding machine, and is polished and polished by an automatic rolling polishing machine. The whole machining process ensures that each weld is even and smooth, with good quality, effectively preventing the tank The inner gallbladder is cracked and deformed during use.

Inner head: A 4mm thick 304 2B stainless steel plate butterfly head is used for the inner head of the tank compartment. The head is formed by one-time hydraulic inflation, with a symmetrical appearance and beautiful appearance. It can buffer fresh milk effectively during use. The impact of the tank head.

Wave-proof board: A dish-shaped wave-proof board with a full wide-angle design. Hydraulic convex forming, fully welded with the inner tank. An arc-shaped flushing edge is welded on the connection part between the wave-proof board and the inner tank. According to the international process standards, it has undergone 6 strict food-grade grinding and polishing processes, so that the vertical connection part of the entire board body becomes a smooth wide angle, so that there is no dead angle, no residue, and no microbial growth in the warehouse. Improve the quality and safety of fresh milk transportation. The staggered opening design of the manholes of the adjacent wave-proof boards can make the fresh milk transported use the kinetic energy of the vehicle to start and stop to form an "S"-shaped circulation in the tank during the transportation process, to realize the function of driving self-mixing. Effectively solve the stratification problem of fresh milk in the tank during long-term static storage or transportation.

Reinforcing ribs of the inner tank: The reinforcement ribs of the tank body are tightly fastened to the inner tank of the tanker according to a certain proportion. This design ensures the firmness of the tank body and effectively prevents the cracking of the welding seam of the inner tank during use. The reinforcing ribs of the tank body are made of a 3mm thick stainless steel plate and rolled into a U shape at one time to ensure the strength and integrity of the tank body. Reserve space between the time and the base to prevent the tank body from directly contacting the vehicle body, causing the loss of cooling energy and the formation of condensed water.

Insulation layer: Imported polyurethane is used, the whole machine is automatically foamed, and the outer layer is laid with a thermal insulation rubber-plastic cotton flame-retardant interlayer, which is uniform and fine in organization, and has a good thermal insulation effect. When transporting liquid food under normal temperature conditions, the temperature change in 24h with a temperature difference of 30°C should not exceed 1.5°C and ensure that it will not burn in the event of an accident.

Automatic breathing valve: Automatically adjust the breathing valve of the tank. The breathing valve opens and closes automatically when the milk outlet at the rear of the tanker opens and closes. Real-time adjustment of the positive and negative pressure balance inside and outside the tank during milk injection and milk discharge from the tanker is efficient and safe. The fully enclosed design can effectively prevent insects and flies from entering the tank through the air inlet of the breathing valve while ensuring the free circulation of air, ensuring the quality and safety of fresh milk during transportation.

CIP cleaning system: The top of the tank is equipped with a spherical rotating nozzle, and the cleaning points are distributed in each independent bin or compartment inside the tanker. Impact force; the cleaner can be sprayed in 360° space because the inner surface of the tank body is in a full wide-angle shape, and all of them have undergone strict food-grade grinding and polishing to ensure excellent cleaning effect.

Anti-skid platform: The anti-skid platform adopts a non-slip pedal formed by stamping and folding of 201 stainless steel plate, which effectively plays a non-slip effect and avoids the failure of anti-skid due to freezing and freezing, to facilitate the operator when washing the tank. Tank tops move around safely. There are drainage ditches on both sides so that the accumulated water on the platform is directionally drained to the ground, which is convenient for the shell to be clean and hygienic.

Temperature gauge installed on truck and 1pc discharge-milk port and 1pc CIP valve

Hot Tags: howo 8000 liters milk delivery truck, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance