Introduction CSCTRUCK Sidelifter have several advanced core technologies and a number of patents, it can transfer containers to other trailers, trucks, or onto the ground. Its characters including big lifting capacity, large working range, wide application range, good versatility and strong...

Introduction

CSCTRUCK Sidelifter have several advanced core technologies and a number of patents, it can transfer containers to other trailers, trucks, or onto the ground. Its characters including big lifting capacity, large working range, wide application range, good versatility and strong guarantee ability, meet the demands of lifting container anywhere. It is widely used for shipping, port, railway, storage and custom etc. Its characteristics of "rapid, vivid, efficiency, convenience" get more and more understanding and approbations.

Features

Double pumps with double branches

The power of pumps is provided by a speed adjustable engine. Hydraulic oil from double pumps drives each component respectively through confluence valve group and multichannel valve group of lift equipment. This kind of hydraulic system can adjust two lift equipment’s' simultaneous motions, ensure stability and reliability of movements during loading and unloading

Load self-adjust patent

The double pumps consist of two parts, a high-pressure pump and a low-pressure pump. Hydraulic oil from double pumps converged by confluence valve drives two lifters. The low-pressure pump will unload at high pressure. Hydraulic system can automatic switchover from low pressure and mass flow to high pressure and little flow steadily. The output power of engine will be fully utilized. Lifters will work steadily and economically.

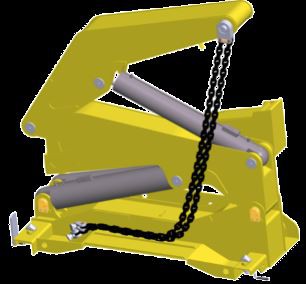

Spreader with chain and twist lock, patent of spreader automatic storageSpreader is mainly composed of chains and twistlocks. Twistlock will rotate and lock corner fittings of container during loading and unloading, and will not drop. During container transportation, twistlock which will not be unsnatched manually can be locked automatically by limiting device. It is convenient, efficient and safety.

Track of suspension point is optimized, so the spreader can be stored automatically when boom being retracted after unloading. Operating comfortableness is increased and safety is i

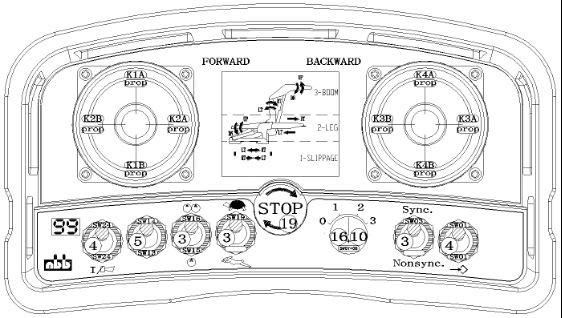

Optimized control system

The side lifter provides a reasonable wireless remote control and two load sensitive electro-hydraulic proportional valves which have pressure compensation. Wireless remote control whose performance includes security, comfortableness and convenience is designed in humanization that the movement of joysticks are consistent with side lifter. The proportional control system allows the side lifter to position the container with precision and steady.

Reasonable protective system

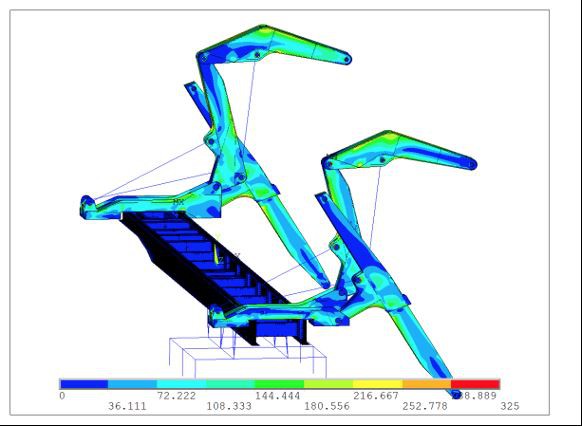

An anti-rollover protection system is installed on stabilizer, it can realize real time supervision in the process of operation whether the vehicle will rollover, give an alarm and lock lifters' movement. At the other side, a baffle is installed on the base of lifter to prevent container going to dangerous area.

High strength steel is used, which reliability is verified by advanced analysis software and tested by experiment. In addition, high quality hydraulic parts, electric parts, reliable retaining mechanism and practical emergency stop are used to increase security.

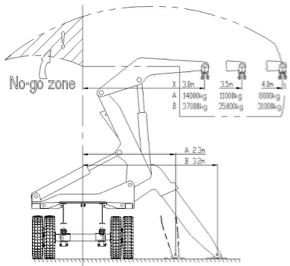

Lifting Chart

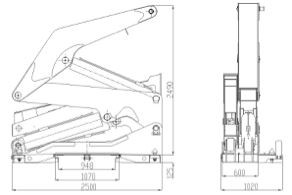

Crane Size

Specification

PARTS | ITEM | DESCRIPTION |

1) General Information | Truck Model | CSC5255SX434 |

Gross vehicle weight | GVW≤35,000 kgs | |

Payload Capacity | ≤19,000kg | |

Crane Lifting Capacity | 37,000kg | |

Drive Mode | 6×4 Left Hand Drive | |

Color Painting | Yellow/blue/white | |

Overall Size | 10080×2495×3980mm | |

Curb weight | 15,600kg | |

Wheelbase | 5575+1400 mm | |

Ground Clearance | 350 mm | |

Rear Overhang | 2030mm | |

Max. Driving Speed | 90km/h | |

2) Engine | Make/Model : | WEICHAI POWER/ WP10.340E22 |

Cylinder No.: | 6 Cylinders inline | |

Displacement | 9726ml | |

Max. Output Power: | 250KW (340PS)@ 2200RPM (SAE) | |

Torque: | 1250Nm@1400-1600RPM | |

Type: | Diesel, Four-stroke, water-cooled, in-line vertical, | |

Aspiration | Turbocharged | |

Norm | Euro II | |

3) Fuel System | Fuel Tank Capacity | 400L, made in aluminum material |

Injection Pump | Mechanical direct injection | |

Injectors | accessible, interchangeable and readily removable | |

Fuel Filters | two in series with water & sediment trap. Filter readily removable for quick maintenance. | |

4) Lubrication System | Manufacturer current standard, Engine lubrication full force feed type and driven by gear. Oil filtration with two replaceable cartridge filters. Oil cooler incorporated in the lubrication system. | |

5) Cooling System | Medium | Water |

Radiador | Tropical, heavy duty type | |

Cooling fan | Manufacturer current standard, Silicone oil cooling fan | |

Thermostat: | Tropical type | |

Warning devices | Audible | |

6) Air-Intake System | Air cleaner type | Heavy duty, dry type |

Pre-filter | Cyclone | |

7) Exhaust System | Emission Standard Euro 2 equivalent. | |

8) Electrical System | Battery Type/Capacity | Heavy duty, 2×12V, 165Ah free maintenance |

Horns | electrical | |

Lighting system | Two adjustable head lights with high and low beams, two parking lights, two combinations stop, tail and direction lights, cabin interior lights, back up lights with automatically activated warning device, instrument panel light, two reflectors and clearance light, plate number light. | |

Window shield wipers | Electrical two speeds | |

Hazard warning flasher | Manufacturer current standard | |

9) CAB

| Medel/Make | Model F3000 D’LONG, Pass ECE-R29 Test |

Type | Four-point suspension | |

Construction | Manufacturer current standard all steel construction | |

Instrument panel | Manufacturer current standard, clearly visible | |

Driver seat | Adjustable(front-rear) | |

Passenger rest bed | One sleeping bed | |

Passenger seat | Fixed | |

No. of seats | 3 including driver | |

Safety belts | provided for both driver and passenger | |

Doors | Central lock, Utilize ignition key | |

Glass | Electric windows glass, Laminated or tempered safety glass | |

Sun visors | Dual, adjustable | |

Mirrors | Heavy duty truck type convex | |

Audio system | Manufacturer current standard | |

10) Chassis

| Frame Construction | Heavy Duty 850×300(8+5)mm |

Bumper | Manufacturer current standard, heavy duty | |

Towing Devices | Front Towing and rear trailer coupling fitted on the chassis frame | |

11) Steering | Model/Make | ZF |

Location | Left hand installed steering | |

System | Hydraulic power assisted steering system | |

12) Clutch | Diameter | Φ430 mm |

Type | Manufacturer current standard | |

13) Transmission | Make/Model: | FAST/10JSD180 |

Gear Numbers: | 10-forwards, 2-reverses | |

Ratio | 1st 14.86, 2nd 11.02, 3rd 8.07, 4th 6.02, 5th 4.46, 6th 3.33 ,7th 2.47, 8th 1.81, 9th 1.35, 10th 1, R1 14.24, R2 3.19 | |

Type: | Heavy duty manual, constant & synchromesh | |

Synchronizer: | Yes | |

Torque: | 1,800N.m | |

14) Suspension

| Front | Semi-elliptic leaf springs with shock absorbers, |

Rear | Semi-elliptic leaf springs reinforced | |

15) Front Axle | Make/Model: | MAN 7.5T |

Type | Steering axle, heavy duty “I – beam’’ construction mounted on heavy duty springs with heavy duty shock absorber. | |

Number | 1(one) | |

Rated Axle Loading | 7,500kg | |

16) Rear Axle

| Model/Make | MAN 13T |

Ratio | 4.769 | |

Type | Welding Axle House, single reduction driven axle, Heavy duty, full floating | |

Number | 2(two) | |

Rated Axle Loading | 13,000kg | |

17) Brake | Type | Pneumatically operated, Drum brake, with ABS |

Running (Service) brake | All wheel dual system. Pneumatically operated, the wheels equipped with drum and manually adjustable type brake shoe. | |

Parking brake | Mechanical spring-operated type acting on rear axle, capable of holding the fully loaded truck (front or reverse) on a 20% gradient. | |

Assistant (Auxiliary) brake | standard pneumatically operated engine brake with operating switch located within the driver’s reach to be installed. | |

18) Wheels & Tires

| Wheels | single front and dual rear |

Size | 12.00R20 | |

PR | 18 | |

Pressure | Single 850Kpa/Dual 850Kpa | |

Max. Load(kg) | Single 3750 kg/Dual 3550 kg | |

Model | DSR266 | |

Brand | DOUBLESTAR or equivalent | |

Type | Tube | |

Number | 10+1pcs spare tire with carrier | |

Position | All position | |

19) Performance | Maximum Speed | 90Km/hr |

Fuel Consumption | <35L/100km | |

20) Platform | Style | Skeletal container frame |

Material | Q235, low alloy carbon steel plate, Mild Steel, Grade Q235, Tensile δ5/% Yield Strength 235Mpa | |

Platform (floor) | Checked steel plate | |

Length | 5850mm | |

Width | 2250mm | |

Twist locks | 4 | |

21) Crane Assembly | Make/Model: | Faoums brand |

| Mounting Position | On truck chassis | |

| Type | Side lifter crane | |

Max Lifting Capacity | 37Ton | |

Max Reach | 4m | |

Outrigger span | 3.2m | |

For lifting container size | 20feet and 40feet | |

22) Specific Requirements | 1) Electrically wire supply, Single phase Three-phase | |

2) Emergency (two batteries): DC 24V (2×12V, 200 A / h) | ||

3) 1 of Electric diesel generator 6.5 kW | ||

4) 2 nos. of 6.5 Kw or 1.5-ton window air conditioning unit | ||

5) 2 nos. of Thermal power unit heaters - 5 kW | ||

6) 6 nos of individual offices desk and chairs ,2 nos of visitor chairs | ||

7) 1 nos of telephone set, 1 nos of internet access | ||

8) Wood floor paved, Manual curtain | ||

9) 1 nos of Plug-in (power source) | ||

10) 1 nos of Hidden exterior staircase | ||

11) 1 nos of 32 inch Smart TV screen | ||

12) 1 nos of Espresso machine, 1 nos of Coffee machines | ||

13) 1 nos of Bathroom Toilet, 1 nos of Bathroom cabinet | ||

14) 6 nos of private wardrobes | ||

Hot Tags: truck mounted side lifter crane, China, manufacturers, suppliers, factory, price, quotation, for sale, high quality, high performance